How Precision-Molded Noryl Impellers Extend Pump Lifespan: A Nobtech Insight

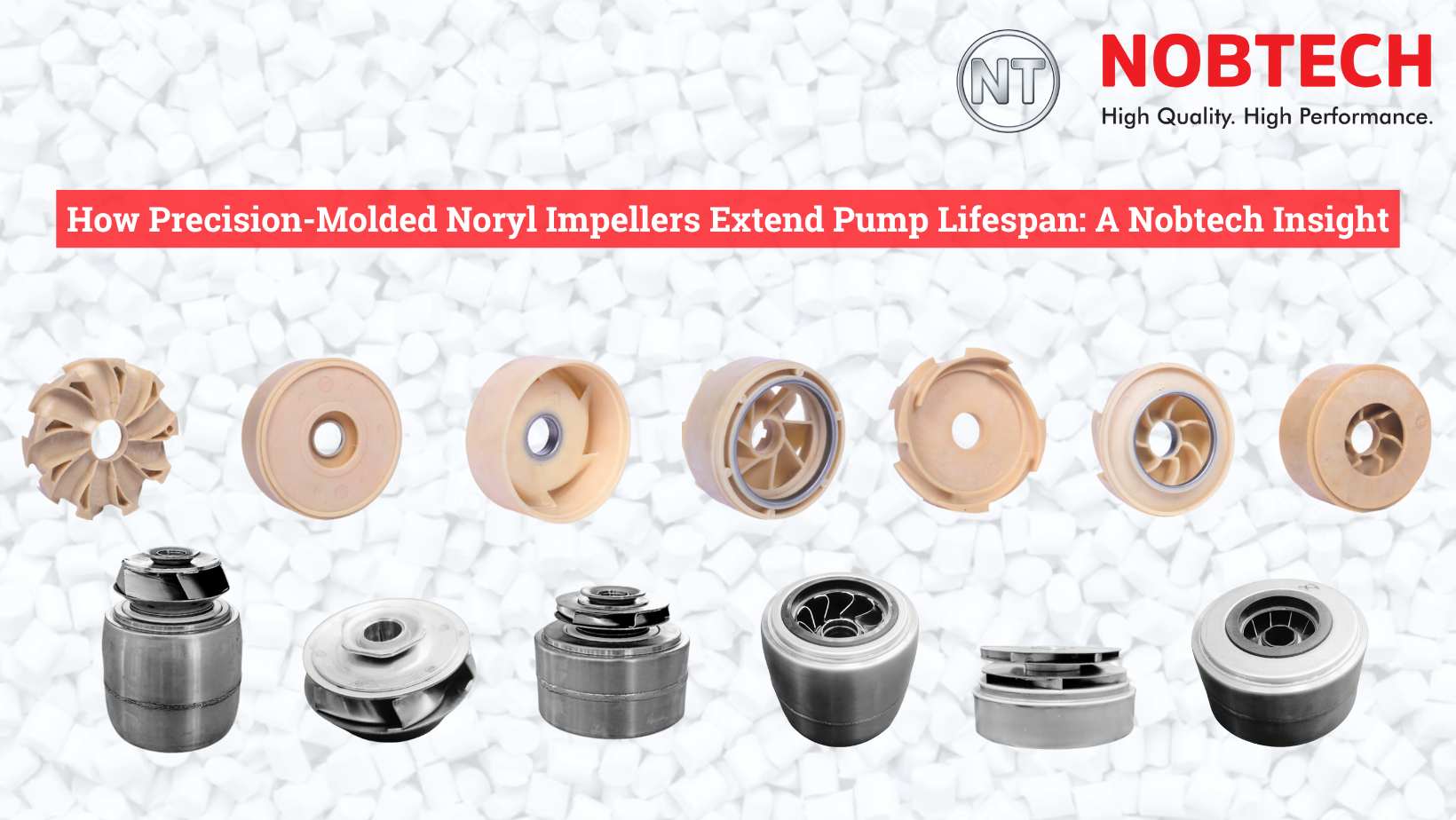

A precision-molded impeller plays a crucial role in the efficiency and performance of various fluid handling equipment, including pumps and compressors. As a highly specialized component, the impeller’s design and manufacturing process directly impact the operational reliability and energy consumption of the machinery it powers. NOBTECH, a leading manufacturer, specializes in producing top-quality stainless steel submersible pump impellers and bowls as well as Noryl submersible pump impellers and diffusers. These components are vital for a broad spectrum of industrial applications, ensuring optimal fluid flow and pressure.

The Significance of Precision-Molded Impellers in Modern Pump Systems

In today’s competitive market, pump manufacturers seek components that combine durability, efficiency, and cost-effectiveness. The NOBTECH company specializes in manufacturing precision-molded impellers that meet these demanding criteria. Precision molding allows for intricate designs that optimize fluid dynamics, reduce turbulence, and minimize energy losses. This advanced manufacturing technique ensures that each impeller maintains strict dimensional tolerances, which is essential for maintaining high efficiency and long service life.

The process of precision molding involves shaping materials such as stainless steel or Noryl plastics into complex geometries with exceptional accuracy. NOBTECH employs state-of-the-art mold fabrication and injection molding techniques to produce impellers that conform to exact specifications. This meticulous process guarantees consistent quality across large production batches, which is critical for OEMs and large-scale procurement agents looking for reliable supply chains.

Benefits of Using Precision-Molded Impellers from NOBTECH

Choosing NOBTECH for your precision-molded impeller needs offers numerous advantages:

Superior Efficiency and Performance

The detailed design facilitated by precision molding ensures smooth fluid flow paths, reducing hydraulic losses. This translates into higher pump efficiency, lower energy consumption, and improved overall system performance. NOBTECH’s impellers are engineered to maximize flow rates while minimizing cavitation risks, making them suitable for various demanding applications.

Enhanced Durability and Reliability

NOBTECH’s impellers are manufactured from high-quality stainless steel or Noryl plastics, materials known for their corrosion resistance and mechanical strength. The precision molding process ensures tight tolerances, reducing the likelihood of defects that can lead to premature failure. This results in longer service intervals and reduced maintenance costs.

Cost-Effective Production

Despite the high level of accuracy, the precision-molded impeller manufacturing process allows for scalable production at competitive prices. NOBTECH’s efficient manufacturing methods enable large OEMs and exporters to source high-quality components without compromising on cost. Additionally, the ability to produce complex geometries reduces the need for assembly of multiple parts, further lowering costs.

Customization and Flexibility

NOBTECH offers tailored solutions to meet specific client requirements. The precision-molding process can accommodate custom blade angles, sizes, and materials, providing OEMs with the flexibility needed to innovate and improve their pump designs.

The Manufacturing Excellence of NOBTECH

With decades of experience in manufacturing stainless steel submersible pump impellers and Noryl impellers, NOBTECH has established itself as a trusted partner for global pump manufacturers. Their commitment to quality control, advanced mold fabrication techniques, and a customer-centric approach make them a preferred choice among OEMs, exporters, and large procurement agencies.

NOBTECH’s facilities are equipped with cutting-edge CNC machining centers and injection molding machines that ensure each precision-molded impeller meets international standards. The company’s rigorous quality assurance protocols include dimensional inspections, material testing, and performance validation to guarantee that every batch delivered is defect-free.

Applications of Precision-Molded Impellers

The versatility of NOBTECH’s precision-molded impellers allows their use across various industries:

- Water supply systems: Ensuring efficient pumping in municipal and industrial water treatment plants.

- Agricultural irrigation: Providing reliable water transfer solutions in farming operations.

- Chemical processing: Handling corrosive fluids with stainless steel impellers designed for chemical resistance.

- Marine and watercraft: Powering water jets and propulsion systems with specialized impeller designs.

- HVAC systems: Enhancing airflow and fluid circulation in heating and cooling applications.

Why Choose NOBTECH for Your Impeller Needs?

For companies seeking high-performance precision-molded impellers, NOBTECH offers unmatched expertise and quality assurance. Their ability to produce complex geometries with tight tolerances ensures maximum efficiency and longevity of the components. Moreover, NOBTECH’s extensive experience serving OEMs globally makes them a reliable partner for bulk procurement and custom solutions.

By partnering with NOBTECH, businesses can benefit from a seamless supply chain of precision-engineered impellers that meet international standards. Whether you need stainless steel or Noryl materials, NOBTECH provides durable, efficient, and cost-effective solutions tailored to your specific requirements.

FAQs

-

What is a precision-molded impeller?

A precision-molded impeller is a highly accurate rotor component produced through advanced molding techniques, designed to optimize fluid flow and enhance pump efficiency. -

Why is precision molding important for impellers?

Precision molding ensures tight dimensional tolerances, smooth surfaces, and complex geometries that improve performance, reduce energy consumption, and increase durability. -

What materials does NOBTECH use for manufacturing impellers?

NOBTECH manufactures impellers using high-quality stainless steel and Noryl plastics to ensure corrosion resistance and mechanical strength. -

Can NOBTECH customize impellers based on specific requirements?

Yes, NOBTECH offers customization options including different sizes, blade angles, and materials to meet unique client specifications. -

How does NOBTECH ensure the quality of its impellers?

NOBTECH employs rigorous quality control processes including dimensional inspections, material testing, and performance validation to guarantee product excellence.

Wrapping Up!

This blog shares a lot about “precision-molded impeller”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/