Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech

Monoblock pumps are vital workhorses in numerous industrial, agricultural, and domestic applications, prized for their compact design and operational efficiency. However, like any sophisticated machinery, their sustained performance and longevity depend significantly on diligent maintenance and the use of high-quality components. Ensuring that these pumps operate at their peak requires a keen understanding of the critical ancillary parts that support them. Investing in the right “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech” is not merely an add-on expense but a strategic decision to safeguard your primary investment, reduce operational downtime, and optimize energy consumption. For businesses relying on consistent water movement, from large-scale agricultural projects to industrial processing plants, the reliability of their monoblock pumps is paramount, and this reliability is directly influenced by the quality of accessories used. Companies like NOBTECH, specializing in core pump components, understand the ecosystem in which their products operate, making the discussion of accessories a pertinent one for their clientele of global pump manufacturers and OEMs.

Understanding Monoblock Pump Vulnerabilities

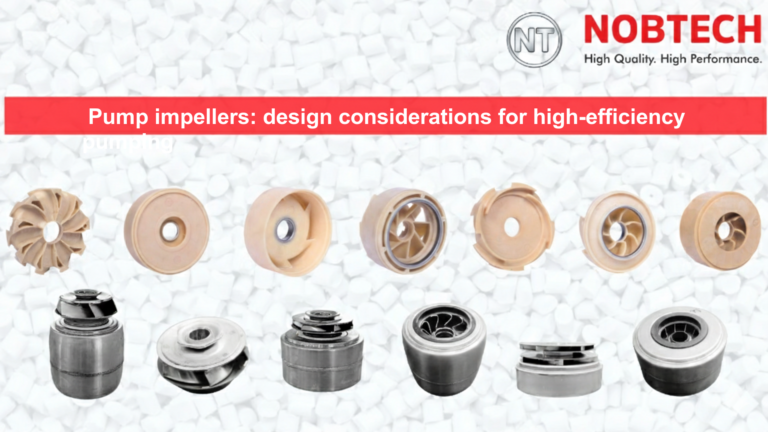

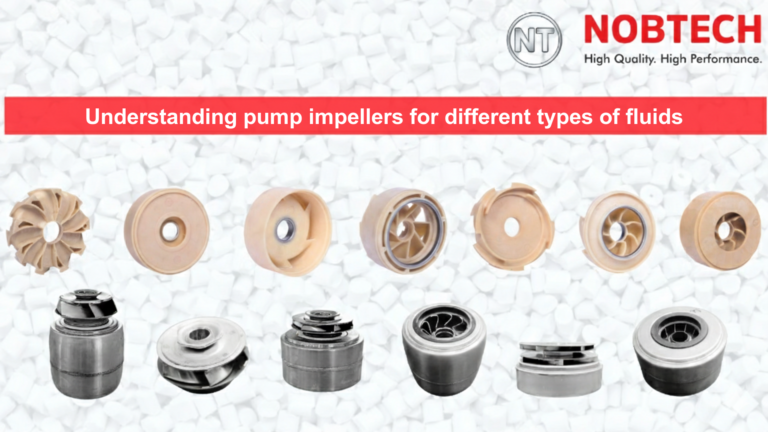

Monoblock pumps, despite their robust construction, are susceptible to various operational hazards if not properly equipped and maintained. Common issues include premature wear and tear of internal components, often exacerbated by abrasive particles in the pumped fluid or by cavitation caused by improper suction conditions. Seal failures can lead to leakage, reduced efficiency, and potential damage to the motor bearings if water ingress occurs. Electrical issues, such as voltage fluctuations or overloading, can also severely impact the motor, which is integrally coupled with the pump in a monoblock design. Many of these vulnerabilities can be significantly mitigated by employing specific accessories designed to protect the pump. For instance, effective filtration can prevent damage to precision parts like impellers and bowls, areas where NOBTECH excels with its manufacturing of Stainless Steel Submersible Pump Impellers and Bowls. Therefore, a proactive approach to incorporating the correct “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech” can translate into substantial long-term savings and enhanced operational reliability.

Core Monoblock Pump Accessories for Optimal Functionality

To ensure that a monoblock pump delivers consistent and efficient performance throughout its service life, a selection of key accessories is indispensable. These components play crucial roles, from monitoring operational parameters to protecting the pump from adverse conditions. Choosing high-quality accessories is as important as selecting the pump itself, as they collectively contribute to a robust and reliable pumping system. This section will delve into some of the most vital Monoblock pump accessories.

Pressure Gauges: The First Line of Defense

Pressure gauges are fundamental for monitoring the operational health of a monoblock pump. Installed on both the suction and discharge sides, they provide real-time data on the pressures the pump is experiencing. A sudden drop or an unusually high reading can indicate potential problems such as blockages, leaks, cavitation, or that the pump is operating outside its designed curve. Early detection of these anomalies allows for timely intervention, preventing more severe damage to the pump’s internal components, including the motor and the wet end. For entities that procure high-quality internal parts like those from NOBTECH, ensuring the pump operates within its specified parameters via diligent monitoring is key to leveraging the longevity of those components. A reliable pressure gauge acts as a constant diagnostic tool, crucial for maintaining optimal performance and efficiency.

Foot Valves and Strainers: Preventing Debris Ingress

Foot valves, typically installed at the end of the suction pipe, are non-return valves that prevent the pump from losing its prime when it’s not in operation. Crucially, most foot valves incorporate a strainer or screen. This strainer plays a vital role in preventing debris, such as sand, pebbles, leaves, or other suspended solids, from entering the pump. The ingress of such abrasive materials can rapidly wear down critical internal components like impellers and diffusers. NOBTECH, a specialist in manufacturing Stainless Steel Submersible Pump Impellers and Bowls as well as Noryl Submersible Pump Impellers and Diffusers, understands the damage such particles can cause. By installing a quality foot valve with an effective strainer, operators protect these precision-engineered parts, ensuring the pump maintains its hydraulic efficiency and extending its lifespan. This is a simple yet highly effective “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech”.

Non-Return Valves (NRVs): Ensuring Unidirectional Flow

Non-Return Valves (NRVs), also known as check valves, are installed on the discharge side of the pump. Their primary function is to ensure that water flows in only one direction, preventing backflow when the pump is switched off. Backflow can cause the pump to spin in reverse, potentially damaging the motor, bearings, and seals. It can also lead to water hammer, a phenomenon where pressure surges occur due to a sudden stoppage of flow, which can stress pipes, fittings, and the pump casing itself. A properly selected and installed NRV is essential for protecting the monoblock pump from these detrimental effects, contributing to the overall stability and safety of the pumping system. Global pump manufacturers who source components from NOBTECH often recommend the use of robust NRVs to protect their assembled units.

Mechanical Seals: The Heart of Leak Prevention

The mechanical seal is one of the most critical components in a monoblock pump, preventing leakage of the pumped fluid along the shaft where it enters the pump housing. A failing seal not only results in fluid loss and reduced pumping efficiency but can also allow water to enter the motor bearings, leading to premature failure and costly repairs. The choice of seal material and design is crucial and depends on the nature of the fluid being pumped, its temperature, and pressure. Investing in high-quality mechanical seals and ensuring their proper installation and maintenance is paramount. While NOBTECH focuses on impellers and bowls, the integrity of the mechanical seal directly impacts the operational environment of these parts. Regular checks and timely replacement of seals are vital aspects of the “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech” strategy.

Control Panels and Starters: Smart Pump Management

Modern monoblock pump installations often benefit significantly from dedicated control panels and motor starters. These units offer much more than simple on/off functionality. They can provide crucial protection against electrical faults such as overloading, under-voltage, over-voltage, and phase imbalance. Advanced control panels may also incorporate features like dry-run protection, which stops the pump if the water source runs dry, preventing severe damage from overheating and cavitation. For businesses that invest in premium pump systems, potentially incorporating components from NOBTECH, a well-designed control panel ensures that the pump operates safely and efficiently, maximizing its lifespan and minimizing the risk of unexpected failures. These panels are essential for automating pump operations and providing a centralized point for monitoring and control, which is particularly valuable for OEMs and large-scale procurement agents integrating pumps into larger systems.

The NOBTECH Advantage in Pump Components

While this discussion focuses on external accessories, it’s crucial to understand the interplay between these accessories and the core components within the pump itself. NOBTECH has carved a niche by specializing in the precision manufacturing of high-quality Stainless Steel Submersible Pump Impellers and Bowls, alongside Noryl Submersible Pump Impellers and Diffusers. These internal parts are the heart of the pump’s hydraulic performance. Global pump manufacturers, exporters, OEMs, and large-scale procurement agents rely on NOBTECH for components that deliver efficiency, durability, and reliability. The strategic use of “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech” serves to protect these high-value internal components. For example, effective strainers prevent abrasion on NOBTECH impellers, and proper electrical protection from control panels prevents motor stress that could indirectly affect the entire pump assembly. Therefore, customers of NOBTECH benefit doubly: first from the superior quality of the core components, and second, from the enhanced lifespan and performance achieved when these components are shielded by appropriate accessories. This holistic approach ensures that the entire pumping system, built around reliable NOBTECH parts, delivers optimal value.

Selecting and Procuring High-Quality Monoblock Pump Accessories

The market offers a wide array of monoblock pump accessories, but not all are created equal. Selecting and procuring high-quality items is essential for achieving the desired protection and performance enhancement. Key factors to consider include material compatibility with the pumped fluid, appropriate pressure and temperature ratings for the application, and the reputation of the accessory manufacturer. For instance, choosing a foot valve made from corrosion-resistant material is vital if dealing with aggressive fluids. Similarly, pressure gauges must be accurate and robust enough to withstand system vibrations and potential pressure spikes.

Businesses, especially large-scale procurement agents and OEMs who source core components from specialists like NOBTECH, understand the importance of component synergy. Just as they trust NOBTECH for critical internal parts, they should apply similar diligence when selecting external accessories. Sourcing from reputable suppliers who can provide technical support and stand by their products is crucial. Often, pump manufacturers themselves will recommend or supply compatible accessories that are proven to work well with their specific pump models. Investing a little more in quality accessories upfront can save significant costs in the long run by preventing premature pump failures and reducing maintenance frequency. For those looking to enhance their pumping systems with reliable internal components, exploring options from NOBTECH at https://nobtech.in/products/ is a step towards overall system integrity, which is then further protected by the right accessories.

Installation and Regular Maintenance of Accessories

Simply purchasing high-quality “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech” is not enough; their correct installation and consistent maintenance are equally important. Incorrect installation can render an accessory ineffective or even detrimental. For example, a pressure gauge installed at the wrong point or a non-return valve installed backward will fail to perform its function and could lead to system malfunctions. It is always advisable to follow the manufacturer’s installation guidelines or engage qualified technicians.

Once installed, a regular maintenance schedule should be established for all accessories. Strainers in foot valves need periodic cleaning to prevent clogging, which can starve the pump of fluid and lead to cavitation. Mechanical seals should be inspected for leaks, and pressure gauges checked for accuracy. Control panels may require checks of electrical connections and calibration of protective relays. This proactive approach to accessory maintenance is an extension of good pump maintenance practice. By keeping these auxiliary components in optimal condition, the monoblock pump itself, including vital internal parts like those manufactured by NOBTECH, is better protected, ensuring sustained performance and a longer operational life. The long-term cost savings from reduced downtime, fewer major repairs, and optimized energy consumption far outweigh the effort and expense of regular accessory upkeep. NOBTECH supports its clients not just with superior components but also by advocating for best practices that ensure the longevity of the entire pumping system.

Frequently Asked Questions (FAQs)

-

What are the most critical monoblock pump accessories to ensure longevity?

Critical accessories include foot valves with strainers to prevent debris ingress, pressure gauges for monitoring operational health, non-return valves to prevent backflow and water hammer, and robust mechanical seals to prevent leaks. For electrically driven monoblock pumps, a quality control panel with motor protection features is also highly essential. -

How often should I inspect my monoblock pump accessories?

Inspection frequency depends on the application, the nature of the fluid being pumped, and the operating environment. However, a general guideline is to inspect strainers monthly, check pressure gauge readings daily or weekly, and inspect mechanical seals for any signs of leakage regularly. Control panel functionality should be verified periodically according to manufacturer recommendations. It’s wise to establish a preventive maintenance schedule tailored to your specific setup. -

Can using quality accessories extend the life of NOBTECH impellers and bowls?

Absolutely. Quality accessories, such as effective strainers in foot valves, directly protect impellers and bowls from abrasive wear. Proper pressure management via gauges and control systems prevents conditions like cavitation or dry running, which can severely damage these NOBTECH components. Thus, investing in good accessories is an investment in the lifespan of the core pump parts. -

Where can businesses source reliable “Essential Accessories for Maintaining Monoblock Pump Performance by Nobtech”?

Businesses should source accessories from reputable suppliers, authorized distributors of pump manufacturers, or specialized industrial equipment providers. It’s important to choose suppliers who offer quality products, technical support, and good warranty terms. Consulting with pump experts or manufacturers like NOBTECH can also provide guidance on compatible and effective accessories for specific pump systems.

Wrapping Up!

This blog shares a lot about “Monoblock pump accessories”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/