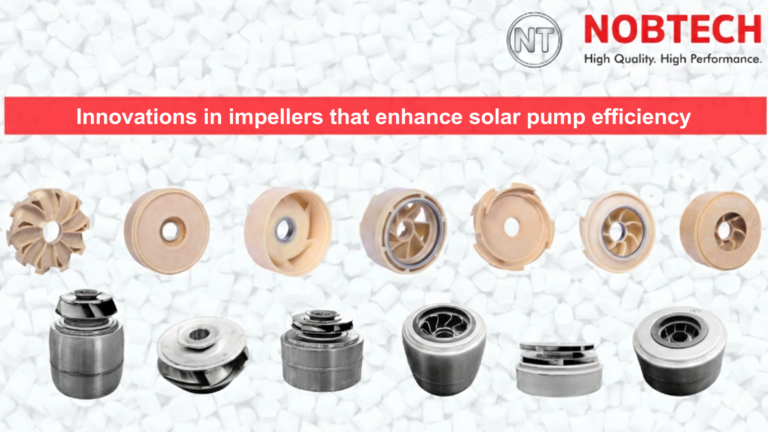

Innovations in impellers that enhance solar pump efficiency

Innovations in impellers are revolutionizing the efficiency of solar pumps, particularly in regions like Mumbai, Maharashtra, India. This has significant implications for industrial sectors where effective water management is crucial. The advancements in pump impellers have paved the way for increased efficiency and durability, making them a reliable choice for various applications. By adopting state-of-the-art…