Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech

The efficiency and longevity of submersible pumps are significantly impacted by the condition and correct installation of their impellers. These critical components are responsible for accelerating fluid and converting velocity into pressure, driving the pump’s performance. When impeller replacement becomes necessary, avoiding common pitfalls is crucial to maintain operational integrity and prevent costly premature failures or system inefficiencies. Understanding the nuances of this process can save businesses significant time and resources, making it essential to get it right the first time. This is especially true for industries relying on robust pumping solutions, where insights into Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech can prove invaluable. For global pump manufacturers, exporters, OEMs, and large-scale procurement agents, partnering with a specialist like NOBTECH, known for its high-quality Stainless Steel Submersible Pump Impellers and Bowls, as well as Noryl Submersible Pump Impellers and Diffusers, ensures access to superior components and expertise.

The Critical Role of Impellers in Submersible Pump Operations

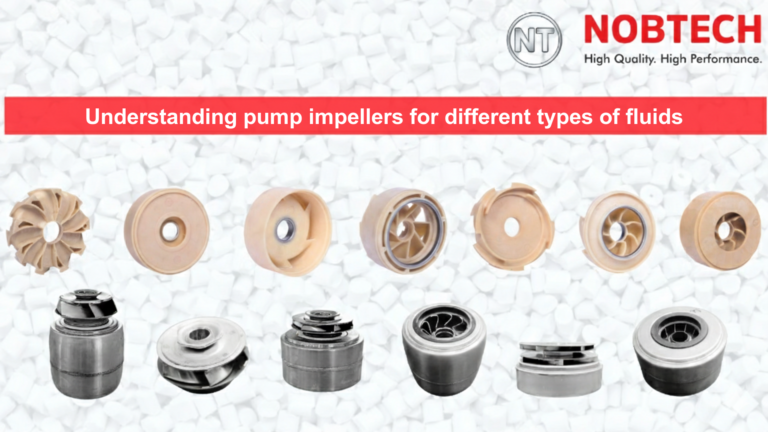

Submersible pumps are workhorses in various sectors, including agriculture, municipal water supply, and industrial applications. At the heart of each pump lies the impeller, a rotating component with vanes or blades that impart kinetic energy to the fluid being pumped. The design, material, and condition of the impeller directly influence the pump’s flow rate, pressure head, and overall efficiency. Worn, damaged, or incorrectly specified impellers can lead to drastically reduced performance, increased energy consumption, cavitation, and even catastrophic pump failure. Therefore, the process of selecting and replacing submersible pump impellers demands precision and an understanding of the potential issues. NOBTECH specializes in manufacturing these vital parts, offering both durable Stainless Steel Submersible Pump Impellers and Bowls, and versatile Noryl Submersible Pump Impellers and Diffusers, catering to diverse operational needs and ensuring that their clients receive components engineered for optimal performance. Recognizing the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech is the first step towards a successful maintenance strategy.

Key Considerations When Replacing Submersible Pump Impellers

A successful impeller replacement extends beyond simply swapping out an old part for a new one. It involves a meticulous approach, from selection to installation, to ensure the pump operates reliably and efficiently post-maintenance. Overlooking certain steps can lead to repeated failures and increased operational costs.

H3: Mistake 1: Incorrect Impeller Selection – A Costly Oversight

One of the most frequent and critical errors is choosing the wrong impeller. This can manifest in several ways: incorrect diameter, wrong vane design for the application, or incompatible material. Using an impeller that’s too large or small will directly affect the pump’s performance curve, leading to either underperformance or motor overload. Similarly, the material must be compatible with the fluid being pumped – corrosive or abrasive fluids require specialized materials like stainless steel, a core offering from NOBTECH. NOBTECH, as a leading manufacturer, provides a wide range of https://nobtech.in/products/, including Stainless Steel Submersible Pump Impellers and Bowls, and Noryl Submersible Pump Impellers and Diffusers, ensuring clients can source the precise component for their specific needs. Global pump manufacturers and large-scale procurement agents rely on NOBTECH‘s expertise to avoid this pitfall, understanding that the right selection is paramount. Failing to address this properly is a primary example of the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech.

H3: Mistake 2: Ignoring Pre-Installation Checks and Pump Condition Assessment

Before installing a new impeller, a thorough inspection of the pump and its associated components is essential. Technicians often overlook examining the pump casing for wear or damage, checking the shaft for straightness and scoring, or assessing the condition of bearings and mechanical seals. Installing a new impeller into a pump with underlying issues is a recipe for premature failure of the new component and potentially the entire pump. For instance, a bent shaft will cause imbalance and vibration, quickly damaging the new impeller and seals. NOBTECH advocates for a holistic approach to pump maintenance, where replacing an impeller is part of a broader system check. This proactive stance helps identify and rectify other potential problems, ensuring the new impeller operates in optimal conditions. Avoiding this oversight is crucial in steering clear of the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech.

H3: Mistake 3: Improper Installation Techniques and Lack of Precision

The physical act of installing the impeller requires care and adherence to manufacturer specifications. Common errors include over-tightening or under-tightening impeller retaining nuts, improper balancing (if required for high-speed applications), incorrect clearance settings between the impeller and the pump casing or diffuser, and even physically damaging the impeller during handling or fitting. Misalignment can lead to excessive wear, vibration, and noise, significantly reducing the pump’s lifespan and efficiency. Technicians should use appropriate tools and follow torque specifications meticulously. NOBTECH components are manufactured to precise tolerances, and their successful installation depends on equally precise workmanship. This is a critical aspect for OEMs and exporters who integrate NOBTECH impellers into their pump assemblies, as installation quality directly reflects on their final product. These installation errors are significant contributors to the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech.

H3: Mistake 4: Neglecting the Replacement of Associated Wear Parts

When an impeller is replaced, it’s often a false economy to reuse old wear rings, gaskets, O-rings, or mechanical seals, even if they appear to be in acceptable condition. These components wear in conjunction with the impeller and are critical for maintaining proper clearances and preventing leaks. An old, worn seal can quickly fail and allow fluid ingress into the motor or bearing housing, leading to far more extensive and costly damage. Similarly, worn wear rings can reduce hydraulic efficiency. NOBTECH advises its clients, particularly global pump manufacturers and large-scale procurement agents who are assembling or refurbishing pumps, to always replace these associated parts as part of a comprehensive impeller replacement. This ensures the integrity of the entire pump system and maximizes the benefits of the new impeller. Skipping this step is another prominent entry in the list of Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech.

Why Choosing Quality Impellers from NOBTECH Matters

The reliability of a submersible pump is directly tied to the quality of its components. Opting for high-grade impellers, such as the Stainless Steel Submersible Pump Impellers and Bowls or the Noryl Submersible Pump Impellers and Diffusers manufactured by NOBTECH, can significantly enhance pump performance and longevity. NOBTECH serves a discerning global clientele of pump manufacturers, exporters, OEMs, and large-scale procurement agents who understand the value of investing in superior parts. These clients demand components that meet stringent quality standards and offer consistent performance. By sourcing from NOBTECH, businesses can reduce the likelihood of premature failures, minimize downtime, and lower overall operational costs. Their commitment to quality engineering ensures that each impeller is designed for optimal hydraulic efficiency and durability. For those looking to procure top-tier components, exploring the https://nobtech.in/products/ offered by NOBTECH is a prudent step towards enhancing pump system reliability. This focus on quality helps avoid many of the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech.

Best Practices for Replacing Submersible Pump Impellers: Ensuring Longevity

To maximize the success of an impeller replacement and the subsequent operational life of the pump, adhering to best practices is non-negotiable. This begins with careful planning and sourcing quality components from reputable manufacturers like NOBTECH. Always consult the pump manufacturer’s service manual for specific instructions, torque values, and clearance specifications. Using the correct specialized tools for disassembly and assembly is also vital to prevent damage to components. Thoroughly clean all parts before reassembly and inspect mating surfaces. Implement a system of double-checks for critical steps like clearance settings and fastener torque. For businesses involved in pump assembly or large-scale maintenance, investing in technician training on these best practices can yield significant returns by minimizing errors. By diligently following these guidelines, many of the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech can be systematically eliminated, leading to more reliable and efficient pumping operations. NOBTECH supports its clients not just with quality products but also with the knowledge that underpins their effective use.

FAQ Section

- What is the most crucial first step when considering replacing a submersible pump impeller? The most crucial first step is accurate problem diagnosis to confirm the impeller is indeed the cause of the pump issue, followed by selecting the correct replacement impeller type and material for the specific application and fluid being pumped, ideally sourced from a specialist like NOBTECH.

- How can I ensure I choose the right impeller from a supplier like NOBTECH? To ensure you choose the right impeller, provide NOBTECH or your supplier with comprehensive details about your pump model, the application (e.g., clear water, slurry, chemical), required flow rate and head, and the properties of the fluid being pumped. Referencing the original pump’s specifications is also essential.

- Why is it important to avoid the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech? Avoiding these common mistakes is critical because errors in impeller replacement can lead to reduced pump efficiency, increased energy consumption, accelerated wear of the pump and motor, costly unplanned downtime, and even catastrophic system failure, all of which negatively impact operational budgets and productivity.

The process of replacing submersible pump impellers is more than a routine maintenance task; it’s an opportunity to restore or even enhance pump performance and efficiency. By being aware of and actively avoiding the common pitfalls, from incorrect selection to flawed installation techniques, businesses can protect their investments and ensure the continued reliability of their pumping systems. Partnering with experienced manufacturers like NOBTECH, who specialize in high-quality Stainless Steel and Noryl impellers and bowls/diffusers, provides access not only to superior components but also to the expertise needed to make informed decisions. Ultimately, understanding and sidestepping the Common Mistakes to Avoid When Replacing Submersible Pump Impellers: Insights from Nobtech contributes significantly to operational excellence and long-term cost savings.

Wrapping Up!

This blog shares a lot about “Replacing submersible pump impellers”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/