Investing in Long-Lasting Noryl Parts for Cost-Effective Pump Operation: Nobtech’s Pick

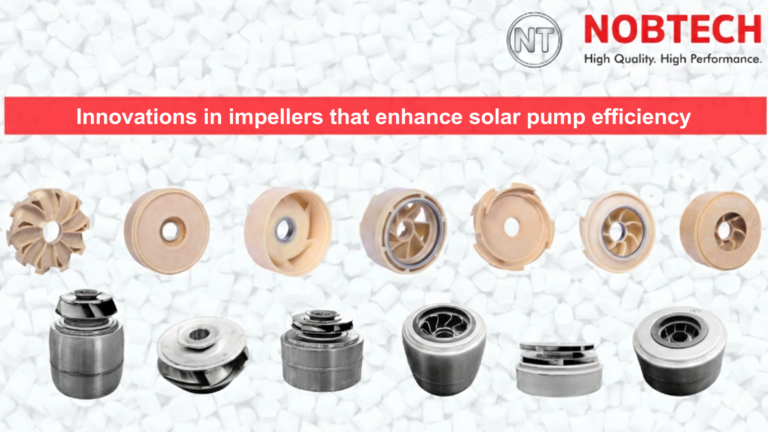

Noryl parts are highly regarded in the plastics industry for their exceptional properties and versatile applications. Noryl, a registered trademark of SABIC, is a type of modified resin that combines the benefits of polyphenylene oxide (PPO) or polyphenylene ether (PPE) resins with polystyrene. This unique blend results in a thermoplastic material that offers high heat resistance, excellent electrical insulation, and superior hydrolytic stability, making it suitable for a wide range of industrial uses. NOBTECH, a leading manufacturer in this domain, specializes in producing top-quality Noryl parts, including impellers and bowls used in various pump systems. To explore their extensive product offerings, visit their product page.

Understanding Noryl and Its Benefits

Noryl parts are favored for their excellent dimensional stability and processability. The incorporation of polystyrene into PPE increases the glass transition temperature above 100°C, enabling Noryl parts to withstand high-temperature environments without deforming. This makes them ideal for electrical and electronic components, where thermal stability is crucial. NOBTECH leverages advanced manufacturing techniques to produce Noryl parts that meet stringent quality standards for global pump manufacturers, OEMs, and large-scale procurement agencies.

NOBTECH’s commitment to quality ensures that each Noryl part is durable, reliable, and resistant to environmental stress cracking. These properties make Noryl an excellent choice for components exposed to harsh conditions, such as water pumps and other machinery parts. The company’s expertise in molding and machining Noryl parts guarantees precision and consistency, essential for critical applications.

Applications of Noryl Parts in Industry

The broad applicability of Noryl parts spans multiple industries. In electronics, NOBTECH supplies Noryl impellers and diffusers that require high thermal stability and electrical insulation. The automotive sector benefits from Noryl’s impact resistance and durability in various under-the-hood components. Additionally, Noryl parts are used in household appliances, medical instruments, and even in the production of air separation membranes for nitrogen generation.

The ability of Noryl to be processed via injection molding or extrusion allows manufacturers to produce complex shapes with high precision. Its surface can be easily printed, painted, or metallized to suit aesthetic or functional requirements. For electrical applications, NOBTECH ensures that the Noryl parts adhere to safety standards while maintaining performance.

Why Choose NOBTECH for Noryl Parts?

NOBTECH has established itself as a trusted supplier of high-quality Noryl parts by focusing on customer needs and providing customized solutions. Their extensive experience in manufacturing impellers and bowls for pumps worldwide has enabled them to serve OEMs, exporters, and large procurement agents effectively. By partnering with NOBTECH, clients gain access to superior products made from premium-grade Noryl resin.

The company’s dedication to innovation means they stay ahead of market trends, continuously improving their manufacturing processes to enhance product quality and performance. Whether you need standard Noryl parts or custom-engineered components, NOBTECH offers reliable solutions backed by technical expertise and quality assurance.

Choosing the Right Supplier

When sourcing Noryl parts, selecting a reputable manufacturer like NOBTECH is essential for ensuring product reliability and longevity. Their strict quality control processes guarantee that each component meets international standards. Moreover, their competitive pricing makes them an attractive partner for large-scale procurement.

For businesses looking to upgrade their existing systems or develop new products with high-performance thermoplastics, NOBTECH provides expert guidance on material selection and design optimization. Their technical support helps clients achieve optimal results with minimal lead times.

FAQs about Noryl Parts

-

What are the main advantages of using Noryl parts?

Noryl parts offer high heat resistance, excellent electrical insulation, impact strength, dimensional stability, and ease of processing. -

Can Noryl parts be customized?

Yes, NOBTECH specializes in manufacturing custom Noryl components tailored to specific application requirements. -

Are Noryl parts suitable for outdoor use?

Noryl’s resistance to environmental stress cracking makes it suitable for outdoor applications when properly designed. -

How does NOBTECH ensure quality?

NOBTECH employs rigorous quality control procedures and advanced manufacturing techniques to produce consistent, high-quality Noryl parts. -

Where can I find more information about Noryl products?

Visit NOBTECH’s product page for detailed specifications and offerings.

Wrapping Up!

This blog shares a lot about “noryl parts”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://slekaind.com/