Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech

The efficiency of a pumping system is paramount in numerous industrial, agricultural, and municipal applications, directly impacting operational costs and system longevity. A critical, yet often nuanced, aspect of achieving peak performance lies in the precise hydraulic synergy between a pump’s impeller and its diffuser. This intricate relationship is fundamental to converting motor energy into fluid movement with minimal losses. For global pump manufacturers, exporters, OEMs, and large-scale procurement agents, understanding and implementing strategies for Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech is not just a technical detail but a significant competitive advantage. Poorly matched components can lead to increased energy consumption, reduced flow rates, premature wear, and even catastrophic pump failure, underscoring the importance of sourcing high-quality, precision-engineered parts.

The Vital Interaction: Impellers and Diffusers in Pump Operation

At the heart of any centrifugal pump are two key components: the impeller and the diffuser (often housed within a bowl in submersible pumps). The impeller, a rotating component equipped with vanes, imparts velocity to the fluid. As the fluid exits the impeller at high speed, it enters the diffuser. The diffuser consists of stationary vanes that are carefully designed to gradually slow down the fluid flow. This deceleration converts the kinetic energy (velocity) of the fluid into pressure energy, which is the ultimate goal of the pump. The efficiency of this energy conversion process is heavily dependent on the geometric compatibility and hydraulic design of both the impeller and the diffuser. NOBTECH, a specialist in manufacturing high-performance pump components, understands this critical interplay and designs its products to optimize this energy conversion, thereby Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech.

Understanding Pump Efficiency and Its Far-Reaching Impact

Pump efficiency is defined as the ratio of the hydraulic power delivered by the pump to the power input to the pump shaft. Higher efficiency means less energy is wasted as heat or noise, translating directly into lower electricity bills and a reduced environmental footprint. For businesses relying on extensive pumping operations, even a small percentage increase in efficiency can result in substantial annual savings. Factors influencing pump efficiency are numerous, including the pump’s specific speed, operating point relative to its Best Efficiency Point (BEP), fluid properties, and mechanical losses. However, the hydraulic design and the precise pairing of the impeller and diffuser stand out as primary determinants. This is where Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech becomes a crucial strategy for end-users and pump manufacturers alike, ensuring that systems operate at their optimal potential, reducing wear and extending service life.

Matching Impellers and Diffusers for Peak Performance

The concept of “matching” goes beyond simply fitting an impeller and diffuser together. It involves a sophisticated understanding of fluid dynamics and mechanical engineering to ensure that the flow leaving the impeller enters the diffuser channels smoothly, with minimal turbulence and energy loss. This includes aligning vane angles, controlling clearances, and ensuring that the area progression within the diffuser is optimized for the flow characteristics generated by the specific impeller. When these components are not properly matched, issues such as flow recirculation, increased hydraulic shock, and cavitation can occur, all of which drastically reduce efficiency and can lead to premature component failure. NOBTECH excels in this domain, focusing on the meticulous design and manufacturing of Matching impellers and diffusers. Their expertise ensures that pump manufacturers can confidently integrate these components, knowing they are engineered for harmonious operation. By sourcing from NOBTECH, companies can significantly simplify the challenge of Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech.

The Science Behind an Ideal Match: Hydraulic Design Nuances

Achieving an ideal match involves careful consideration of several hydraulic design parameters. The number of impeller vanes versus diffuser vanes, their respective angles, the inlet and outlet diameters, and the axial and radial clearances between rotating and stationary parts all play critical roles. For example, the diffuser vane inlet angle must align with the absolute flow angle from the impeller outlet across the intended operating range of the pump. Any mismatch here creates incidence losses. NOBTECH employs advanced design principles and manufacturing precision to control these parameters, thereby ensuring that their impeller and diffuser sets contribute significantly to Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech. Pump manufacturers partnering with NOBTECH benefit from this deep engineering focus, receiving components that are ready for integration and high performance.

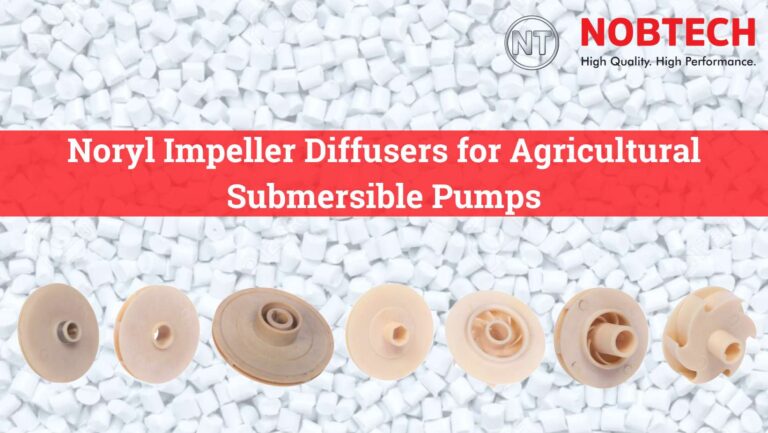

Material Selection: The Role of Stainless Steel and Noryl from NOBTECH

The choice of material is also critical for both performance and longevity, especially when dealing with different fluid types and operating conditions. NOBTECH specializes in manufacturing both Stainless Steel Submersible Pump Impellers and Bowls and Noryl Submersible Pump Impellers and Diffusers. Stainless steel offers excellent durability, corrosion resistance, and strength, making it ideal for demanding applications involving aggressive fluids or abrasive particles. Noryl, a modified polyphenylene oxide (PPO) thermoplastic, provides a lightweight, cost-effective alternative with good mechanical strength and dimensional stability, suitable for clean water applications. NOBTECH guides its clients – global pump manufacturers, exporters, OEMs, and large-scale procurement agents – in selecting the appropriate material to ensure optimal performance and longevity, further contributing to Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech. Their extensive product range can be explored at https://nobtech.in/products/.

NOBTECH: Your Strategic Partner for Enhanced Pump Efficiency

For global pump manufacturers, exporters, OEMs, and large-scale procurement agents looking to elevate their product offerings, NOBTECH stands as a reliable partner. Their specialization in manufacturing high-quality Stainless Steel Submersible Pump Impellers and Bowls and Noryl Submersible Pump Impellers and Diffusers is backed by a commitment to precision engineering. By focusing on the critical task of Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech, the company provides components that form the backbone of reliable and efficient pumping systems. Choosing NOBTECH means opting for components designed for optimal hydraulic performance, leading to pumps that meet and exceed customer expectations for efficiency and durability. Pump manufacturers can enhance their product lines and gain a competitive edge by integrating NOBTECH‘s meticulously crafted components.

Manufacturing Excellence at NOBTECH

NOBTECH’s commitment to quality is evident in its manufacturing processes. State-of-the-art machinery, rigorous quality control protocols, and the use of premium raw materials ensure that every impeller and diffuser set meets stringent specifications. This manufacturing excellence is fundamental to producing perfectly matched components that are key to Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech. The consistency and precision offered by NOBTECH translate into reliable pump performance for their B2B clients worldwide.

Serving a Global Clientele with NOBTECH Solutions

NOBTECH is dedicated to serving a diverse international clientele, including prominent pump manufacturers, exporters, and OEMs. Understanding the varied needs of different markets and applications, NOBTECH provides tailored solutions and robust support. Their focus on Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech allows their clients to deliver superior pumping solutions to their respective end-users, reinforcing their market position. For businesses looking to source high-performance pump internals, NOBTECH offers a comprehensive portfolio accessible via their website https://nobtech.in/.

The Economic and Environmental Dividends of Optimized Pump Systems

Investing in optimally matched impellers and diffusers yields significant economic and environmental benefits. Reduced energy consumption is the most immediate advantage, leading to lower operational expenditures for the end-user. This efficiency also translates to a smaller carbon footprint, aligning with global sustainability goals. Pumps that operate efficiently experience less stress on components like bearings and seals, resulting in longer service intervals and reduced maintenance costs. By prioritizing Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech, manufacturers contribute to a more sustainable and economically sound approach to fluid handling. NOBTECH components are designed with these long-term benefits in mind.

Overcoming Common Pumping Challenges with NOBTECH Components

Pump systems often face challenges such as cavitation, vibration, premature wear of components, and overall underperformance relative to design specifications. Many of these issues can be traced back to a suboptimal hydraulic design, particularly a mismatch between the impeller and diffuser. Cavitation, for instance, can be exacerbated if the diffuser cannot efficiently handle the flow from the impeller, leading to localized pressure drops. Vibration may arise from hydraulic imbalances caused by an improper match. NOBTECH addresses these challenges proactively by providing precisely engineered and matched impellers and diffusers. This commitment ensures that pumps built with NOBTECH components are better equipped to deliver smooth, efficient, and reliable operation, truly Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech.

Frequently Asked Questions (FAQ)

- What is the primary goal of matching impellers and diffusers in a pump? The primary goal is to ensure the smoothest possible transition of fluid from the rotating impeller to the stationary diffuser, converting velocity energy into pressure energy with minimal hydraulic losses, thereby maximizing the overall efficiency and performance of the pump. 2. How does NOBTECH ensure the quality and precision of its impellers and diffusers for effective matching? NOBTECH employs advanced design software, precision manufacturing techniques, high-quality material selection (including stainless steel and Noryl), and stringent quality control checks throughout the production process to ensure that each component meets exact specifications for optimal hydraulic performance and matching. 3. Why is Maximizing Pump Efficiency: Matching Impellers and Diffusers with Nobtech a critical consideration for pump manufacturers and OEMs? For pump manufacturers and OEMs, achieving maximum efficiency provides a significant competitive advantage by offering end-users lower operating costs, enhanced reliability, and a longer pump lifespan. This directly translates to greater customer satisfaction and a stronger market reputation. 4. What specific types of impellers and diffusers does NOBTECH specialize in manufacturing? NOBTECH specializes in the manufacturing of Stainless Steel Submersible Pump Impellers and Bowls designed for durability and resistance in challenging conditions, as well as Noryl Submersible Pump Impellers and Diffusers, which offer a lightweight and cost-effective solution for various water applications.

Wrapping Up!

This blog shares a lot about “Matching impellers and diffusers”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/