Reducing Cavitation: The Impact of High-Quality Diffusers on Pump Performance by Nobtech

Pump cavitation is a critical phenomenon in fluid mechanics and engineering that can significantly impact the performance and longevity of pumping systems. It occurs when the pressure within a pump drops below the vapor pressure of the liquid, leading to the formation of vapor-filled cavities or bubbles. These cavities, often called voids or vapor bubbles, can collapse violently when they move into higher-pressure regions within the pump, causing shock waves that may damage impeller blades, bowls, and other pump components. As a result, pump cavitation is a major concern for engineers and manufacturers aiming to ensure efficient and durable pump operation.

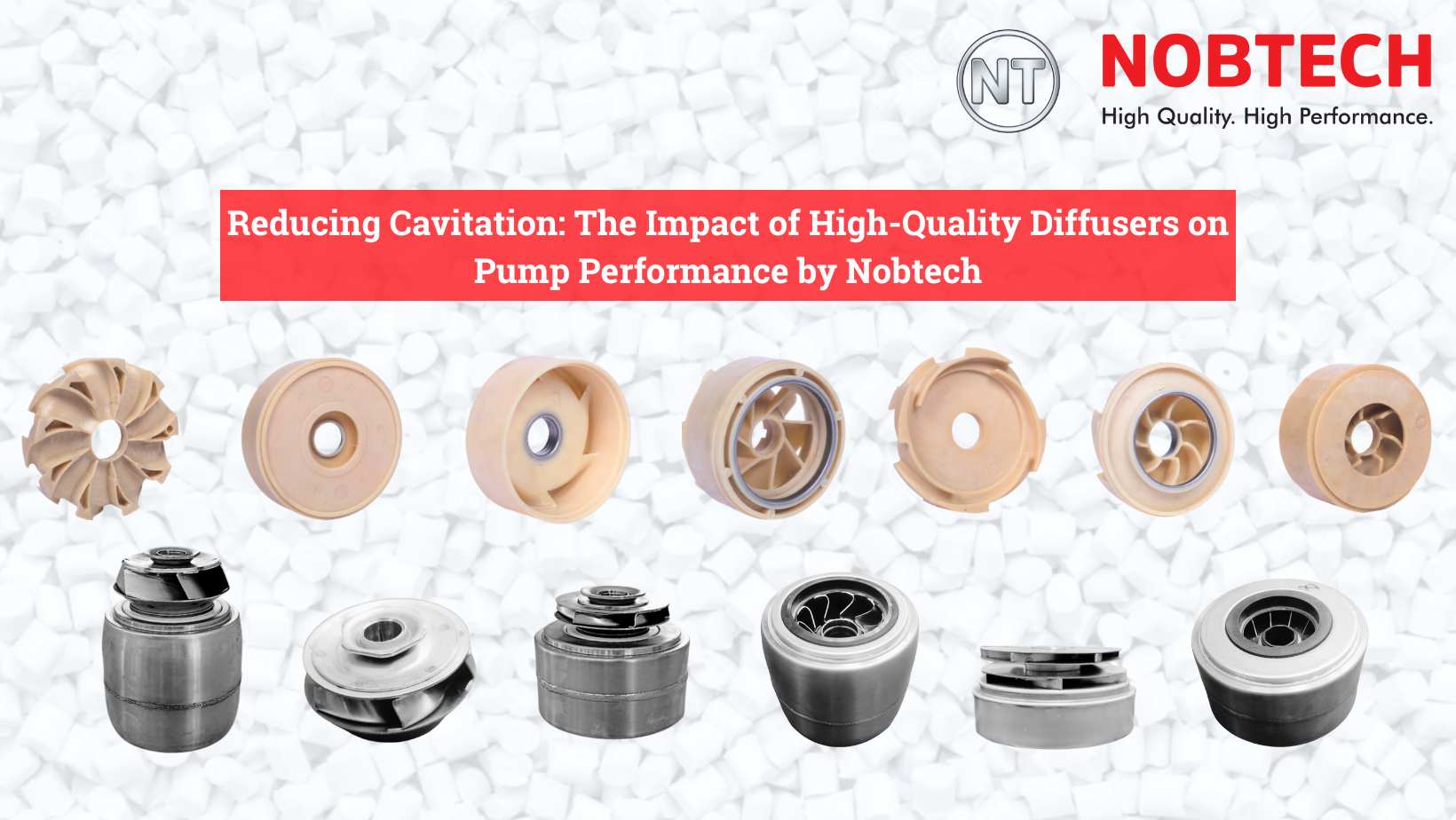

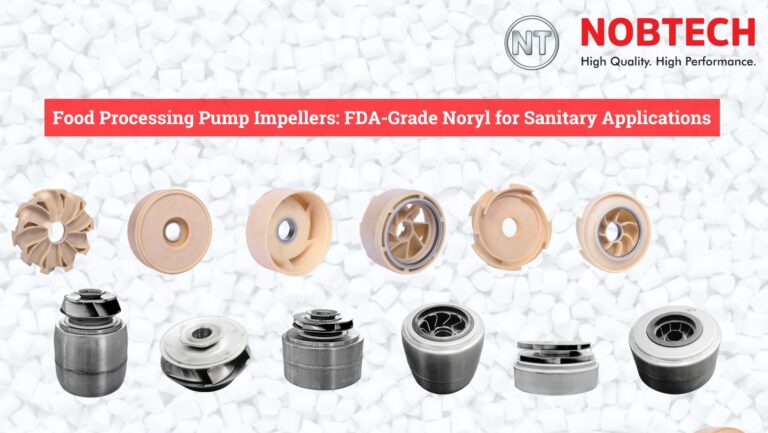

At NOBTECH, we understand the importance of preventing pump cavitation to maintain optimal pump performance. NOBTECH specializes in manufacturing high-quality stainless steel submersible pump impellers and bowls as well as Noryl submersible pump impellers and diffusers. Our products are designed with precision to withstand the harsh conditions that often lead to cavitation, providing reliable solutions for global pump manufacturers, exporters, OEMs, and large-scale procurement agents. You can explore our extensive range of products at https://nobtech.in/products/.

Understanding the causes of pump cavitation is essential for effective prevention. Cavitation typically occurs when there is a high fluid velocity combined with a drop in pressure, often due to improper pump selection, inadequate inlet pressure, or operating conditions outside the recommended parameters. For instance, running a pump at a flow rate higher than its design capacity can cause local pressure drops, fostering cavitation. Similarly, insufficient inlet pressure or blockages in the suction line can lead to vapor bubble formation.

How Pump Cavitation Affects Pump Performance

Pump cavitation can cause a range of operational issues. Initially, it results in noise and vibration, which are clear indicators of cavitation activity. Over time, the repeated implosion of vapor bubbles causes surface erosion and pitting on impeller blades and other internal components. This erosion not only reduces the efficiency of the pump but also leads to costly repairs and downtime. In severe cases, cavitation can cause catastrophic failure of the pump.

To combat these problems, NOBTECH offers specialized stainless steel impellers and bowls that are engineered to resist cavitation-induced wear. Our products are manufactured using advanced techniques to ensure durability and performance even under demanding conditions. Additionally, our Noryl impellers and diffusers are lightweight yet robust solutions suitable for various applications.

Preventing Pump Cavitation

Prevention strategies involve proper pump selection, system design, and operational practices. Ensuring adequate inlet pressure is vital; this can be achieved through proper piping design, maintaining sufficient liquid levels, and avoiding excessive pipe friction losses. Installing suction stabilizers or priming devices can also help maintain consistent inlet conditions.

Operationally, it’s essential to operate pumps within their recommended parameters. Regular monitoring of flow rates, inlet pressures, and noise levels can help detect early signs of cavitation. NOBTECH’s high-precision impellers and bowls are designed to optimize flow paths and minimize pressure drops that lead to cavitation.

The Role of NOBTECH in Combating Pump Cavitation

NOBTECH’s expertise in manufacturing stainless steel submersible pump impellers and bowls as well as Noryl impellers and diffusers plays a crucial role in mitigating cavitation issues. Our products are crafted to enhance flow efficiency and withstand the erosive effects of vapor bubble collapse. By choosing NOBTECH’s components, pump manufacturers can improve their equipment’s resistance to cavitation-related damage, thereby extending service life and reducing maintenance costs.

Our commitment to quality and innovation makes us a trusted partner for OEMs and large-scale procurement agents worldwide. Whether you need impellers for centrifugal pumps or diffusers for submersible systems, NOBTECH provides tailored solutions that meet international standards.

FAQ about Pump Cavitation

-

What are the main signs of pump cavitation?

Noise, vibration, and a decrease in pump efficiency are common signs indicating cavitation activity. -

Can pump cavitation be completely prevented?

While it cannot always be entirely prevented, proper system design, component quality, and operational practices can significantly reduce its occurrence. -

How does NOBTECH help in reducing cavitation?

NOBTECH manufactures impellers and bowls designed to optimize flow paths and resist erosive effects caused by cavitation, ensuring longer-lasting pump performance. -

Is pump cavitation harmful to the environment?

Indirectly, yes. Cavitation damages can lead to leaks or spills if pumps fail, which may harm the environment. Proper prevention minimizes such risks. -

What industries most affected by pump cavitation?

Industries like water treatment, oil & gas, chemical processing, agriculture, and manufacturing are highly susceptible to cavitation issues.

Wrapping Up!

This blog shares a lot about “pump cavitation.” To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/. To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/.