Future Trends in Impeller and Diffuser Technology for Submersible Pumps: Insights by Nobtech

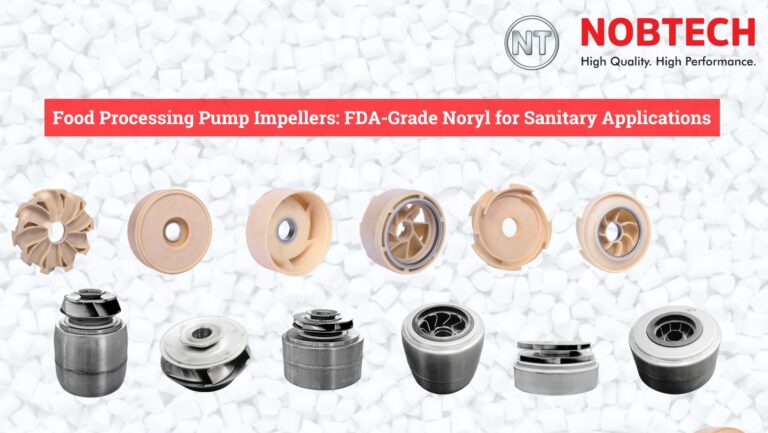

Impeller technology has become a cornerstone in modern fluid handling systems, playing a vital role in various industries such as water pumping, HVAC, automotive, and aerospace. At the heart of many pumps and compressors, impellers are engineered components designed to transfer energy to fluids, thereby increasing pressure and flow rate. Leading industry players like NOBTECH have set the benchmark in manufacturing high-quality impellers, specializing in stainless steel submersible pump impellers and bowls, as well as Noryl submersible pump impellers and diffusers. Their expertise ensures that businesses worldwide receive durable and efficient impeller solutions tailored to their specific needs.

Understanding the fundamentals of impeller technology is essential for selecting the right component for your application. NOBTECH’s commitment to innovation and quality manufacturing makes it a trusted partner for pump manufacturers, exporters, OEMs, and large-scale procurement agents globally. Their extensive product range and adherence to international standards have established NOBTECH as a leader in impeller technology.

Impeller technology encompasses various types and designs, each suited to particular operational requirements. The core function of an impeller is to accelerate fluids outward from the center of rotation, thereby increasing their pressure and flow. This process is crucial in centrifugal pumps and compressors, where efficient energy transfer directly impacts system performance. NOBTECH’s manufacturing facilities produce a wide array of impellers made from premium materials like stainless steel and Noryl, ensuring longevity and resistance to corrosion in demanding environments.

The Role of Impeller Technology in Pump Efficiency

Impeller technology significantly influences the efficiency and reliability of pumps and compressors. Modern impeller designs focus on optimizing flow paths, reducing turbulence, and minimizing wear. NOBTECH’s impellers are crafted with precision engineering to meet these criteria, ensuring maximum performance. Their stainless steel submersible pump impellers are particularly popular for applications requiring corrosion resistance, such as water treatment plants and offshore operations.

NOBTECH’s expertise extends to designing open, semi-closed, and closed impellers, each tailored for specific operational conditions. Open impellers are favored for handling solids and debris, making them ideal for wastewater and sewage applications. Closed impellers, on the other hand, provide higher efficiencies in clean water systems and are used extensively in large-scale industrial pumps. The semi-closed design offers a balance between durability and performance, suitable for mixed fluid handling.

Advancements in Impeller Design and Manufacturing

The evolution of impeller technology has been driven by innovations in materials science and manufacturing processes. NOBTECH leverages advanced casting techniques and precision machining to produce impellers with tight tolerances and superior surface finishes. This not only enhances efficiency but also extends the lifespan of the components.

Additionally, NOBTECH’s focus on custom solutions allows clients to benefit from impeller designs that are specifically optimized for their unique system parameters. Whether it’s improving flow rates or reducing cavitation risks, their team of engineers collaborates closely with customers to develop tailored impeller technology solutions.

Impeller Technology in Centrifugal Compressors

In centrifugal compressors, impeller technology is equally critical. The impeller’s shape, blade angle, and rotational speed determine the compressor’s capacity to generate high-pressure airflow efficiently. Open impellers are preferred at higher speeds due to their ability to handle more complex flow conditions without restrictions. NOBTECH’s impellers are designed to withstand high rotational speeds while maintaining structural integrity.

Applications Beyond Pumping: Water Jets and Aerospace

Impellers are not limited to traditional pumping systems. They are also integral to water jet propulsion systems used in high-speed boats and marine vessels. These impellers resemble small propellers but are optimized for specific fluid dynamics requirements. In aerospace, impeller technology contributes to turbochargers and jet engines by facilitating compressed airflow essential for engine performance.

NOBTECH’s commitment to quality manufacturing ensures that their impellers meet the rigorous demands of these specialized applications. Their products are trusted by global OEMs seeking reliable components capable of operating under extreme conditions.

Why Choose NOBTECH for Your Impeller Needs?

Partnering with NOBTECH provides numerous advantages:

- High-Quality Materials: Stainless steel and Noryl provide corrosion resistance and durability.

- Customizable Designs: Tailored solutions for specific operational needs.

- Global Reach: Serving pump manufacturers, exporters, OEMs, and large procurement agents worldwide.

- Advanced Manufacturing: State-of-the-art facilities ensure precision and consistency.

- Comprehensive Product Range: From open to shrouded impellers suitable for various applications.

Their extensive experience ensures that clients receive not only top-tier products but also technical support throughout the project lifecycle.

FAQs about Impeller Technology

1. What is impeller technology?

Impeller technology involves designing and manufacturing rotors that increase the pressure and flow of fluids in pumps and compressors, using advanced engineering principles to optimize performance.

2. Why is material selection important in impeller technology?

Material selection impacts corrosion resistance, strength, and longevity. NOBTECH specializes in stainless steel and Noryl impellers to meet diverse environmental challenges.

3. How does NOBTECH ensure the quality of its impellers?

NOBTECH employs advanced casting, machining, and quality control processes to produce high-precision impellers that adhere to international standards.

4. Can NOBTECH customize impellers for specific applications?

Absolutely. NOBTECH offers customized solutions tailored to unique operational parameters, ensuring optimal performance.

5. What industries benefit from impeller technology?

Industries such as water treatment, oil & gas, marine propulsion, HVAC, automotive, and aerospace all benefit from advanced impeller technology provided by NOBTECH.

Wrapping Up!

This blog shares a lot about “impeller technology”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/