The role of impellers in reducing pump cavitation risks

In the bustling industrial landscape of Mumbai, Maharashtra, impellers play a vital role in enhancing operational efficiency for pumps. Companies looking to minimize risks associated with pump cavitation must consider the quality of their impellers carefully. These components are crucial for maintaining fluid dynamics in systems ranging from water pump impellers to more complex setups, ensuring optimal performance in various applications. By investing in high-quality pump impellers, businesses can significantly improve their process efficiency and reliability.

Why Choose The role of impellers in reducing pump cavitation risks from NOBTECH

Cavitation can severely impede the efficiency and longevity of pump operations. By using superior-quality impellers from NOBTECH, businesses can significantly reduce the risks associated with this phenomenon. Impellers are engineered to enhance fluid velocity while minimizing turbulence, which are key factors in preventing cavitation. The advanced design of NOBTECH impellers ensures that they function seamlessly even under challenging conditions, thereby maintaining fluid integrity and effective operation.

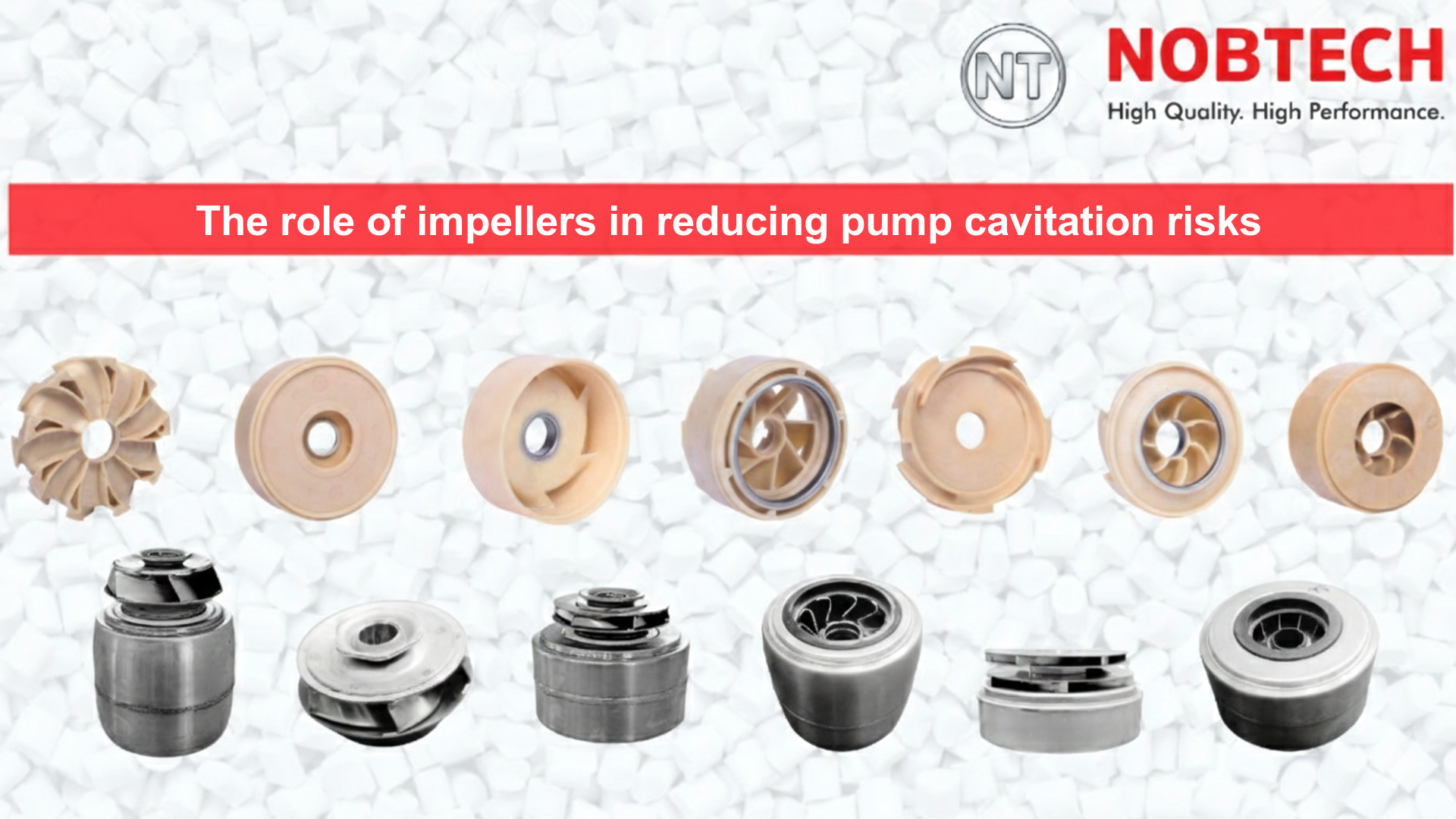

Furthermore, the use of different impeller types—such as closed, semi-closed, and open impellers—allows for tailored solutions specific to the application needs. Closed impellers, for example, offer higher efficiency and are ideal for clear-fluid applications, while open impellers work effectively with slurries and other viscous materials. By selecting the appropriate impellers from NOBTECH, companies can optimize performance and safeguard against cavitation-related damages.

Benefits of Premium The role of impellers in reducing pump cavitation risks

Investing in premium-grade impellers significantly enhances the operational capabilities of pumps. NOBTECH‘s water pump impellers are designed to withstand high workloads and provide exceptional durability, thus reducing maintenance costs over time. The precision engineering involved ensures consistent performance, making these impellers ideal for various industrial applications.

Additionally, the emphasis on high-quality materials means that the impellers remain resilient against wear and tear, ensuring long operational life. This is critical for sectors that rely on continuous fluid movement, where downtime can lead to significant financial losses. By choosing NOBTECH‘s solutions, businesses gain a competitive edge through improved efficiency and reliability.

The role of impellers in reducing pump cavitation risks: Technical Specifications

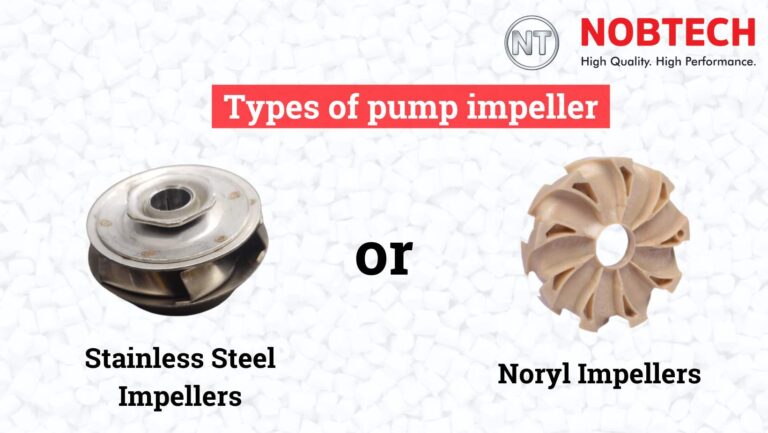

Understanding the technical specifications of pump impellers is essential for effective operation. NOBTECH offers a range of impeller types, including Noryl submersible pump impellers and stainless steel designs, crafted to meet specific fluid dynamics needs. These impellers feature detailed designs that consider the nature of the fluid being pumped and the potential for cavitation under pressure.

Each impeller type comes with its own set of specifications catering to various fluid characteristics—be it viscosity, temperature, or corrosiveness. For instance, stainless steel impellers excel in environments where durability is paramount, whereas plastic (Noryl) designs are preferred for lightweight and corrosion resistance. This careful selection of materials and engineering creates a synergy that significantly minimizes cavitation risks, enhancing system reliability.

Industrial Applications of The role of impellers in reducing pump cavitation risks

Impellers find extensive applications across diverse industries, from water treatment plants to petrochemical facilities. The ability of NOBTECH impellers to perform under varying conditions makes them suitable for both high-flow and high-pressure scenarios. For instance, booster pump impellers are integral in systems requiring significant pressure increases, while coolant pump impellers play a critical role in maintaining machinery at optimal temperatures.

Moreover, industries that operate in high-switch frequency environments benefit from using reliable pump impellers. With NOBTECH‘s expert design and manufacturing capabilities, companies can experience fewer breakdowns and longer operational lifespans for their pumping systems.

Quality Standards & Certifications

Every impeller manufactured by NOBTECH adheres to international quality standards, ensuring that clients receive only the best. Stringent testing across various parameters guarantees the effectiveness and reliability of each pump impeller. Certifications from recognized bodies affirm the robustness of NOBTECH‘s products, further assuring clients about their investment in quality.

Custom Manufacturing Capabilities

At NOBTECH, custom manufacturing capabilities allow for tailored solutions catering to specific requirements. Depending on the type of fluid or the operational parameters, they can produce impellers that match your precise needs. This flexibility is crucial for industries that require specialized performance characteristics from their pump components.

Export & Bulk Order Services

For businesses looking to procure in bulk, NOBTECH offers export services that streamline the logistics of obtaining pump impellers. With a focus on providing competitive pricing and efficient delivery options, companies can expect timely and reliable supply of high-quality impellers that meet their operational demands.

Technical Support & After-Sales

Post-purchase support is critical for maximizing the lifespan of pump systems. NOBTECH provides comprehensive technical support and after-sales services to ensure that clients can efficiently integrate and maintain their impeller systems.

FAQ

-

What makes The role of impellers in reducing pump cavitation risks from NOBTECH superior to competitors?

The impellers are developed using high-grade materials, ensuring precision and durability, backed by NOBTECH‘s quality control standards. -

Can NOBTECH provide custom The role of impellers in reducing pump cavitation risks for specific applications?

Absolutely! NOBTECH offers custom tooling alongside OEM support and engineering assistance tailored to unique operational needs. -

What are the delivery timelines for bulk orders of impellers?

Bulk pricing benefits come with swift export logistics, allowing for prompt global shipping of NOBTECH products. -

How does NOBTECH ensure quality standards for The role of impellers in reducing pump cavitation risks?

Quality control is paramount at NOBTECH, with certifications, rigorous testing procedures, and thorough inspection systems in place.

Wrapping Up!

This blog shares comprehensive insights about “The role of impellers in reducing pump cavitation risks” and industrial pump component solutions. To explore our complete range of stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

For advanced solar pumps and pumping systems, discover innovative solutions at- https://www.slekaind.com/