Types of Impeller

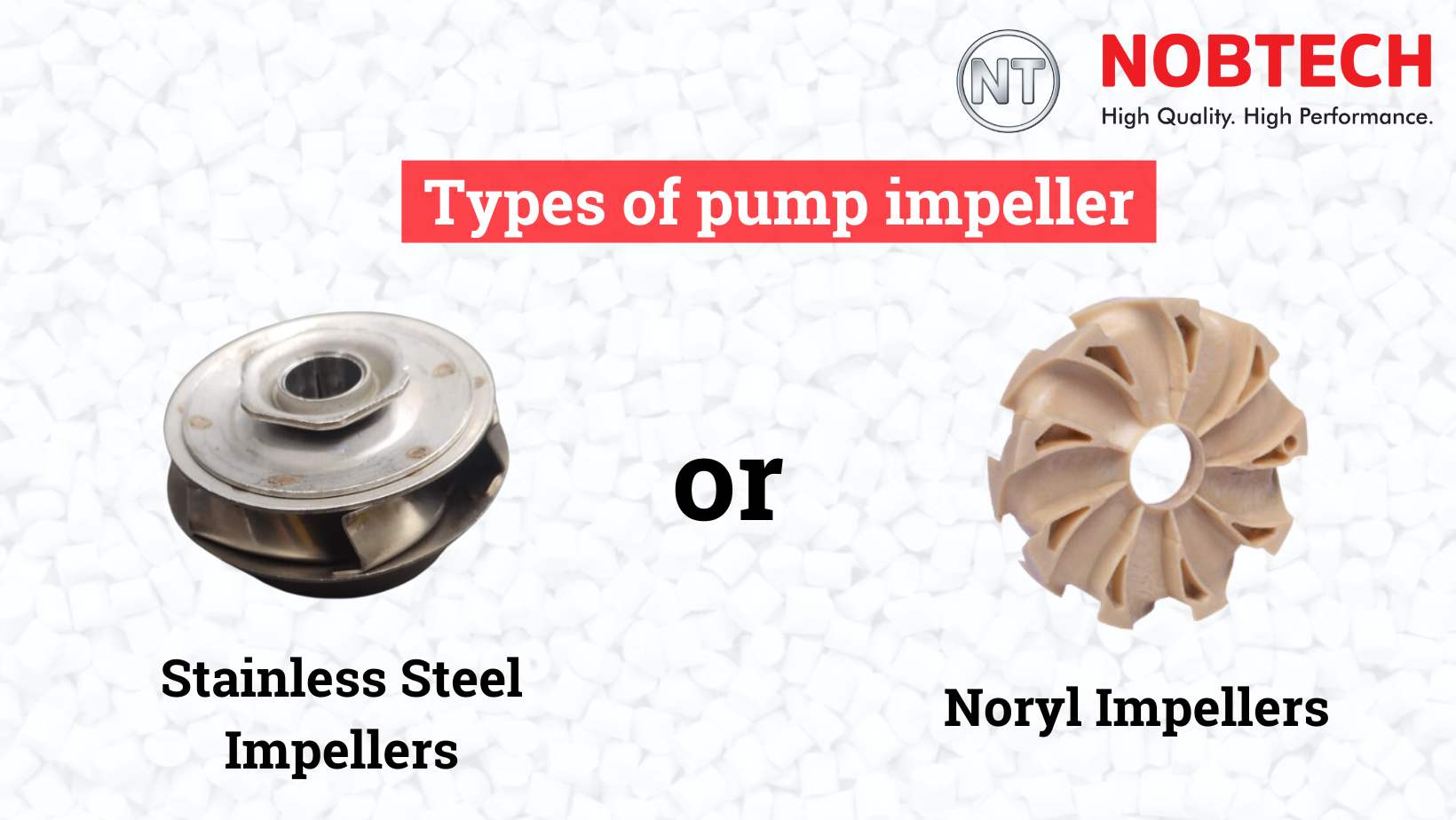

Choosing the right pump impeller is crucial for your submersible pump’s performance. At Nobtech Enterprise, we’re experts in making top-quality impellers. We specialize in two main types: Noryl impellers and stainless steel impellers. Each type has its own benefits for different pumping needs. Whether you’re pumping harsh chemicals or need high efficiency, the impeller you pick matters a lot. In this guide, we’ll explain the different types of impeller Noryl and stainless steel impellers. We’ll help you understand which one is best for your pump. Nobtech Enterprise is here to help you boost your pump’s performance with the perfect impeller.

Types of Impeller

Types of Noryl Impellers

1. Closed Noryl Impellers

Closed Noryl impellers feature fully enclosed vanes connected by shrouds on both sides. This design maximizes efficiency by preventing liquid from slipping over the vane tips. They’re ideal for pumping clean or thin liquids, offering high hydraulic efficiency and stable performance curves. However, they may not be suitable for liquids containing solids or fibrous materials due to potential clogging.

2. Open Noryl Impellers

Open Noryl impellers have exposed vanes without shrouds, allowing for easier passage of solids and fibrous materials. This design reduces the risk of clogging and simplifies maintenance and cleaning. While slightly less efficient than closed impellers, they excel in handling dirty water or liquids with small suspended solids. Open impellers are also more tolerant of wear, making them suitable for slightly abrasive applications.

3. Semi-Open Noryl Impellers

Semi-open Noryl impellers strike a balance between closed and open designs. They feature vanes attached to a base plate but lack a front shroud. This configuration offers a good compromise between efficiency and solids-handling capability. Semi-open impellers are versatile, suitable for a wide range of applications including moderately dirty water and liquids with some suspended solids.

4. Vortex Noryl Impellers

Vortex Noryl impellers, also known as recessed impellers, create a whirlpool effect to move liquids. They’re set back from the pump’s suction inlet, allowing large solids to pass through without direct contact. This design excels in handling liquids with high solid content, long fibrous materials, or gases. While less efficient than other designs, vortex impellers offer superior clog resistance and are ideal for wastewater applications.

Types of Stainless Steel Impellers

1. Closed Stainless Steel Impellers

Closed stainless steel impellers combine the efficiency of a closed design with the durability of stainless steel. They offer excellent performance in clean liquid applications while resisting corrosion and wear. These impellers are ideal for high-pressure applications, hot liquids, and environments where chemical resistance is crucial. Their robust construction makes them suitable for industrial processes requiring consistent, high-efficiency operation.

2. Open Stainless Steel Impellers

Open stainless steel impellers provide the benefits of an open design with enhanced durability. They excel in handling abrasive liquids and slurries due to their wear-resistant properties. The open design allows for easy passage of solids and simplifies maintenance. These impellers are particularly well-suited for mining applications, industrial wastewater, and other demanding environments where both solids-handling capability and material strength are essential.

3. Semi-Open Stainless Steel Impellers

Semi-open stainless steel impellers offer a versatile solution for various industrial applications. They combine the balanced performance of a semi-open design with the strength and corrosion resistance of stainless steel. These impellers are suitable for applications involving moderately abrasive liquids or where occasional solids may be present. They provide a good compromise between efficiency, solids-handling, and durability in challenging pumping environments.

4. Custom Stainless Steel Impellers

At Nobtech Enterprise, we specialize in creating custom stainless steel impellers tailored to unique pumping requirements. These bespoke solutions are designed to address specific challenges such as unusual fluid properties, extreme operating conditions, or specialized industrial processes. Our custom impellers can optimize pump performance, improve efficiency, and extend equipment life in applications where standard designs fall short.

Conclusion

Picking the right impeller is key to getting the best performance from your pump. At Nobtech Enterprise, we offer a wide range of Noryl and stainless steel impellers. Each type has its own strengths. Noryl impellers are great for efficiency and handling chemicals. Stainless steel impellers are tough and last long in harsh conditions. Think about what you’re pumping and where you’re using the pump. This will help you choose the best impeller. Remember, the right impeller can save you money on energy and repairs in the long run. Need help deciding? Contact Nobtech Enterprise. We’re here to make sure you get the perfect impeller for your needs.

FAQs

What’s the difference between Noryl and stainless steel impellers?

Noryl impellers are lightweight and resist chemicals well. Stainless steel impellers are very strong and good for tough conditions.

How do I know which impeller type is best for my pump?

Consider what you’re pumping, how often you use the pump, and where it’s used. Contact us for expert advice.

Can Nobtech Enterprise make custom impellers?

Yes, we can create custom impellers to meet your specific pumping needs.

How often should I replace my pump impeller?

It depends on use, but generally every 2-5 years. Signs of wear or reduced performance mean it’s time to replace.

Are Nobtech’s impellers more efficient than standard ones?

Yes, our impellers are designed for high efficiency, which can save energy and improve pump performance.

How do I maintain my pump impeller?

Regular cleaning and inspection are key. Follow the manufacturer’s guidelines and contact us for specific advice.

Read Also: Plastic Impellers for Submersible Pumps

Wrapping Up!

This blog shares a lot about “Types of Impeller”

To know more about solar pumps in agriculture, visit-slekaind.com/our-products/

To know more about Noryl impellers and diffusers, do visit- https://nobtech.in/products/