Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components

Thinking…

Considering Project Scope

Okay, I understand the client wants a 1200-word blog post, and needs specific formatting. No introduction, and no images. I’m taking this on board and focusing on the content planning to meet these requirements.

Analyzing the Briefing

I’ve carefully reviewed the client’s detailed brief. I’m noting the specific word count, formatting requirements (no intro, no images), keyword density for ” Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components,” and usage of “NOBTECH”. I’m also capturing all the target audience and product details.

Organizing the Structure

Alright, I’m setting up the core sections now. I’ve noted the need to introduce the topic directly with a paragraph, then I’ll break down the challenges of corrosion, introduce Noryl, its advantages, and then focus on NOBTECH’s specific offerings and the concluding wrapping-up note.

Formulating Content Plan

I’m now outlining the specific content for each section. I’ve noted the need to introduce the topic directly with a paragraph, then I’ll break down corrosion issues, introduce Noryl, then focus on NOBTECH’s offerings and wrapping up. I’m planning my keyword use and commercial phrases throughout.

Finalizing the Structure

Okay, I’m now finalizing the blog post structure. I’m breaking down each section and ensuring I include the core keywords, commercial phrases, and mentions of NOBTECH, all while remembering the client’s guidelines.

Clarifying Content Breakdown

I’m now detailing the specific content for each section, including the introduction and FAQ. I’m noting keyword integration and NOBTECH mentions throughout, as instructed.

Confirming Detailed Content Plan

I’m now fully committed to the detailed plan. I’ve ensured the structure aligns with the client’s guidelines, including word count, keywords, commercial phrases, and NOBTECH mentions throughout each section, and an FAQ section. I’m ready to begin generating content.

Formulating the Blog Post

I’ve crafted a comprehensive structure for the blog post, including the introductory paragraph, seven H2 sections, an FAQ, and conclusion, all aligned with the client’s guidelines. I’m now drafting the content, keeping in mind the focus keyword density, commercial tone, and specific NOBTECH mentions throughout.

Finalizing Content Generation Strategy

I’m now ready to draft the content, section by section. I’ll maintain strict adherence to the client’s guidelines, including keyword density, commercial tone, and NOBTECH mentions. I’ll meticulously track word count and ensure a seamless, professional flow.

Finalizing Content Generation

I’ve crafted a comprehensive content generation plan, complete with keyword integration, commercial phrasing, and detailed section breakdowns. I’ll closely monitor word count, NOBTECH mentions, and the focus keyword, ensuring the blog post meets the client’s brief. I’m ready to begin writing!

The operational reliability and longevity of pumping systems are paramount in numerous industrial, municipal, and agricultural applications. A critical factor influencing this performance is the ability of pump components to withstand corrosive environments, which can otherwise lead to premature failure, costly downtime, and reduced efficiency. For businesses seeking robust solutions, a thorough grasp of material science and its impact on component durability is essential. This exploration delves into the specifics of Noryl, a high-performance thermoplastic, and its significant advantages in pump construction, particularly focusing on Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components, a key consideration for optimizing fluid handling systems. NOBTECH has established itself as a premier manufacturer in this domain, offering components that address these critical challenges.

The Pervasive Challenge of Corrosion in Pumping Systems

Corrosion is an electrochemical process that degrades materials, particularly metals, due to reactions with their environment. In pumping systems, components are frequently exposed to a wide array of fluids, from potable water to aggressive chemicals, industrial effluents, and saltwater. The nature of the pumped medium, its temperature, pH level, and the presence of dissolved solids or gases all contribute to the corrosive potential. Traditional materials like cast iron or certain grades of stainless steel, while suitable for many applications, can succumb to specific types of corrosion, including pitting, crevice corrosion, or general wastage. This degradation not only compromises the structural integrity of pump components like impellers and diffusers but also adversely affects hydraulic performance, leading to increased energy consumption and reduced flow rates. The economic ramifications are substantial, encompassing repair and replacement costs, operational interruptions, and even potential environmental hazards if containment is breached. Therefore, selecting materials inherently resistant to the specific corrosive challenges of an application is a foundational step in designing durable and efficient pumping solutions. For global pump manufacturers and large-scale procurement agents, sourcing components that offer superior corrosion resistance is a strategic imperative.

Noryl: A High-Performance Thermoplastic for Demanding Applications

Noryl, a trade name for a family of modified Polyphenylene Oxide (PPO) resins, stands out as an engineering thermoplastic renowned for its exceptional combination of mechanical, thermal, and chemical properties. It is created by blending PPO with polystyrene or other polymers, allowing for a range of grades with tailored characteristics. Key attributes of Noryl include high strength and stiffness, excellent dimensional stability even at elevated temperatures, low moisture absorption, and good electrical insulating properties. Crucially for pump components, Noryl exhibits broad chemical resistance, making it an ideal candidate for applications involving fluids that would corrode many conventional materials. Its hydrolytic stability ensures that it maintains its properties even after prolonged exposure to hot water, a significant advantage in many pumping scenarios. NOBTECH leverages these inherent qualities by specializing in the precision manufacturing of Noryl Submersible Pump Impellers and Diffusers, engineered to deliver sustained performance. The lightweight nature of Noryl also contributes to easier handling and potentially lower inertial loads within the pump assembly, offering an additional, often overlooked, benefit.

Deep Dive: Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components

The exceptional performance of Noryl in corrosive environments stems from its chemical structure. Unlike metals, Noryl does not suffer from galvanic corrosion or rust. Its resistance to a wide spectrum of chemicals, including many acids, bases, and aqueous solutions, is a primary reason for its selection in demanding pump applications. This inherent chemical inertness means that components made from Noryl, such as those expertly manufactured by NOBTECH, do not leach contaminants into the pumped fluid, a critical factor in potable water systems or food processing applications. The low water absorption rate of Noryl is another vital aspect contributing to its corrosion resistance and dimensional stability; materials that absorb significant amounts of water can swell, soften, or become susceptible to hydrolytic degradation, issues largely mitigated with Noryl. For submersible pumps, which are constantly immersed in the pumped medium, this property is particularly beneficial. Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components involves appreciating how these material characteristics translate into extended service life and reliable operation, even when handling moderately aggressive well water or treated effluents. NOBTECH ensures that their Noryl components, including impellers and diffusers, are manufactured to precise tolerances, maintaining the material’s integrity and maximizing its inherent resistance. This focus on quality is fundamental to delivering on the promise of corrosion-resistant solutions. Careful selection of Noryl grades suitable for specific chemical exposures further enhances the Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components, ensuring optimal performance for end-users.

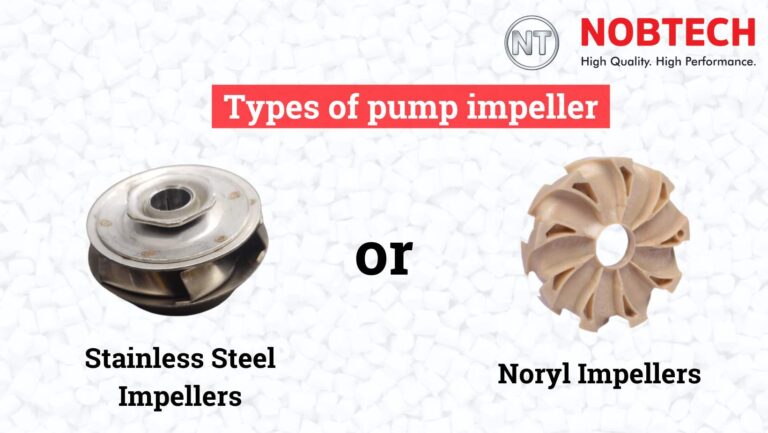

NOBTECH’s Manufacturing Excellence and Commitment to Global Partners

NOBTECH (https://nobtech.in/) has carved a niche as a specialist manufacturer of high-quality pump components, catering to a discerning global clientele that includes pump manufacturers, exporters, Original Equipment Manufacturers (OEMs), and large-scale procurement agents. The company’s expertise extends to both Stainless Steel Submersible Pump Impellers and Bowls and Noryl Submersible Pump Impellers and Diffusers, demonstrating a comprehensive understanding of material science and its application in fluid dynamics. For their Noryl components, NOBTECH employs advanced injection molding techniques and stringent quality control protocols. This ensures that each impeller and diffuser meets precise dimensional specifications and material integrity standards, which is crucial for optimal hydraulic efficiency and long-term durability. The ability to consistently deliver high-grade components makes NOBTECH a trusted partner for businesses looking to enhance the performance and reliability of their pump offerings. By focusing on the critical aspect of Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components, the company empowers its clients to make informed decisions that lead to superior product outcomes. Procurement agents and OEMs can confidently integrate NOBTECH’s Noryl parts into their assemblies, knowing they are built for endurance in challenging environments. Explore their diverse product range at https://nobtech.in/products/.

Strategic Advantages for OEMs and Procurement Agents

For OEMs and procurement agents, partnering with NOBTECH for Noryl pump components offers tangible commercial and operational benefits. The superior corrosion resistance of Noryl translates directly into extended mean time between failures (MTBF) for pumps, reducing warranty claims and enhancing brand reputation for reliability. By integrating NOBTECH’s Noryl impellers and diffusers, manufacturers can offer pumps that are better suited for a wider range of applications, including those involving mildly corrosive fluids where metallic components might falter prematurely. This broadens market reach and provides a competitive edge. Furthermore, the long-term cost-effectiveness is a significant draw; while the initial material cost might differ from some traditional options, the reduced maintenance, lower replacement frequency, and enhanced operational lifespan offered by Noryl components result in a lower total cost of ownership. Large-scale procurement agents benefit from NOBTECH‘s capacity for consistent supply and adherence to quality standards, ensuring a reliable stream of high-performance parts. A deeper Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components allows these B2B clients to articulate the value proposition more effectively to their own customers, emphasizing longevity and reduced operational expenditure.

Diverse Applications and Industries Capitalizing on Noryl’s Resilience

The inherent corrosion resistance and robust mechanical properties of Noryl make it a preferred material for pump components across a multitude of industries. In water treatment plants, Noryl impellers and diffusers handle various chemically treated waters without degradation, ensuring consistent performance. The chemical processing industry benefits from Noryl’s ability to withstand exposure to a range of chemical solutions, making it suitable for transfer pumps and dosing systems. Desalination plants, particularly those employing reverse osmosis, often deal with saline water and pre-treatment chemicals; Noryl’s resistance to such media is a significant advantage. In agriculture and irrigation, where water quality can vary greatly and may contain dissolved minerals or fertilizers that are corrosive to metals, Noryl components supplied by manufacturers like NOBTECH offer extended service life. Even in residential and commercial building services for boosting water pressure or circulating hot water, Noryl’s hydrolytic stability and resistance to scaling make it an excellent choice. The Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components is key to unlocking these applications, providing reliable solutions where other materials might prove inadequate. This versatility makes Noryl an economically sound choice for pump manufacturers aiming to serve diverse markets.

Optimizing Longevity: Best Practices for Noryl Pump Components

While Noryl provides exceptional corrosion resistance, the overall lifespan and performance of any pump system also depend on proper system design, installation, and operational practices. Ensuring that the pump operates within its recommended hydraulic range (Best Efficiency Point – BEP) minimizes stress on components, including Noryl impellers and diffusers. Avoiding cavitation, which can physically damage even robust materials, is crucial. Regular inspection of the overall system, though less frequent for Noryl’s corrosion aspect, helps identify any emergent issues like seal wear or bearing problems that could indirectly affect component life. For applications with abrasive solids, while Noryl has good wear characteristics for a thermoplastic, pre-filtration or selection of appropriate pump designs can further enhance longevity. Fundamentally, a comprehensive Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components allows users to confidently deploy these parts in suitable environments, knowing they are less susceptible to chemical attack. However, a holistic approach to pump system management will always yield the best long-term results, ensuring that the inherent benefits of materials like Noryl are fully realized.

Frequently Asked Questions

1. What inherent properties of Noryl make it so effective against corrosion in pump components?

Noryl, a modified Polyphenylene Oxide (PPO), is inherently resistant to a wide range of chemicals, including many acids, bases, and salt solutions, because of its stable chemical structure. Unlike metals, it doesn’t experience galvanic corrosion. Its very low moisture absorption rate also prevents swelling or degradation from hydrolysis, which is crucial for components constantly immersed in fluids, contributing significantly to the Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components.

2. How do NOBTECH’s Noryl pump components, such as impellers and diffusers, compare to traditional metal alternatives in aggressive fluid environments?

In environments where fluids are corrosive to common metals like cast iron or even some stainless steel grades, NOBTECH’s Noryl components often provide superior longevity and reliability. They resist chemical attack that would degrade metals, preventing pitting, crevice corrosion, or general material loss, thereby maintaining hydraulic efficiency and structural integrity for longer periods.

3. Why is a clear Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components particularly important for pump manufacturers and OEMs when selecting materials?

For pump manufacturers and OEMs, selecting the right materials directly impacts product performance, reliability, warranty costs, and market reputation. A clear Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components enables them to design and offer pumps suitable for a broader range of challenging applications, ensuring customer satisfaction and potentially reducing long-term operational costs for the end-user, thus providing a competitive advantage. NOBTECH supports this by providing high-quality, durable Noryl parts.

The strategic selection of materials is foundational to the development of durable, efficient, and reliable pumping systems. The unique properties of Noryl, particularly its exceptional chemical and hydrolytic stability, make it an outstanding choice for components subjected to corrosive environments. A comprehensive Understanding Corrosion Resistance in Nobtech’s Noryl Pump Components allows engineers, procurement specialists, and OEMs to leverage these benefits fully. NOBTECH, with its specialization in manufacturing high-quality Noryl submersible pump impellers and diffusers, as well as stainless steel components, stands as a key partner for global pump manufacturers seeking to enhance their product offerings and deliver lasting value. By choosing advanced materials like Noryl, the industry can move towards more sustainable and cost-effective fluid handling solutions.

Wrapping Up!

This blog shares a lot about “Corrosion-resistant Noryl pump components”

To know more about stainless steel and Noryl submersible impellers and bowls, visit- https://nobtech.in/products/

To explore solar pumps and pumping systems, do visit- https://www.slekaind.com/